I shed a few grateful tears the other day when I first opened up the early results of our survey. Hundreds of you have not only taken the time to answer the basic survey questions, but you’ve also written beautiful paragraphs of encouragement and support. When I made up the survey I was only hoping to receive some concrete opinions and perhaps a little enthusiasm to help launch me into the initial design phase for our next batch of patterns. Instead, I received that plus so much more. Even though I thought I was keeping my insecurities and concerns to myself, so many of you are perpceptive or have perhaps walked a similar path before. You took a big nebulous cloud of unexamined fears and anxiety, named it all for me and then showed me how to move on. Thank you!

Here are a few of the comments that I am just so grateful for:

“I really value the work you’re doing. I know balancing work & family needs is a real challenge. The challenges don’t go away – they change as everyone gets older – kids, parents, & you. But so do the rewards ( or maybe out standards drop 😉). Hang in there. Trust your gut. You got this.”

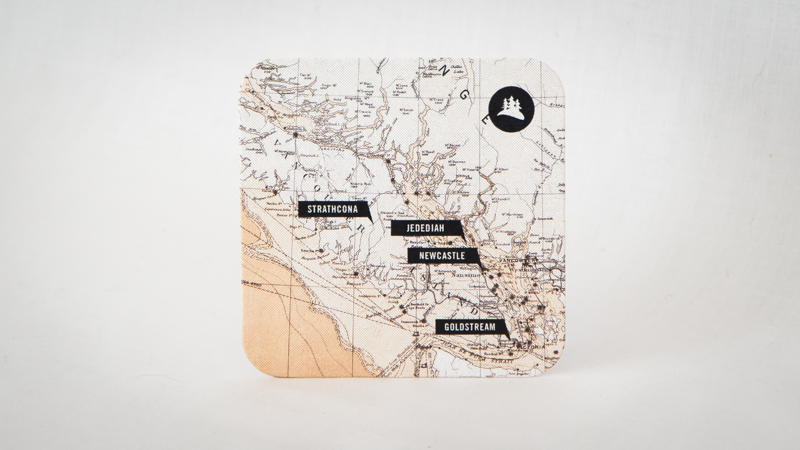

“Thank you for some lovely patterns, superb instructions, helpful sew alongs and tutorials. I sew these patterns again and again because they produce well fitting, beautiful and hardwearing garments. I love the details and finishes, the henley placket and the cuffs of the Strathcona, the hood lining of the Finlayson being smaller than the hood which gives a lovely fold back finish. The welt pockets excellent instructions of the Belvedere waistcoat and all the tips in the online sew along.”

“Keep up the amazing work! As a male sewist there isn’t much out there that I get to make for myself, and finding your site years ago was what made me brave enough to try making clothes for myself.”

“I also live in BC and have a small acreage, so I really love the updates to your blog about your property, even though they have nothing to with sewing!”

Some of you were concerned that I plan to depart from menswear design entirely. Don’t worry, menswear patterns will remain the main focus for Thread Theory. I only seek to refresh and envigorate myself by approaching things from a slightly different direction for a while.

The survey results are still streaming in steadily and I have a lot of thinking yet to do so it is far too early to say what my plans will be for this shift of focus. In the meantime, your outpouring of understanding has made me feel so much more connected to the sewing community and, as a result, I am newly eager to get designing!

Another unanticipated outcome from the survey results is that I am now clear that many of you have been enjoying my homesteading blog posts. In the “Any other comments?” answer box at the end of the survey, person after person wrote that they have been enjoying these posts and hope I keep writing them. Wow! I had considered stopping them as I suspected they were tolerated at best…I’m glad to hear that isn’t the case! I really enjoy writing about our new lifestyle and will continue with much more confidence now. With that in mind, here is a little peek into our long post-Christmas winter days:

While driving Noah into the little town nearest us earlier this week (we attend an action packed toddler group at the local community hall) he fell asleep when only minutes away from home. He’s usually only napping in the afternoon now but has had at least four teeth coming in over the last few days so that wore him out enough to fall asleep as early as 9:30 in the morning. Rather than wake him I decided to just keep on driving and head 45 minutes south to a big menswear retail chain to do a little RTW research for Thread Theory. Once Noah woke we headed into the shop and he pushed a buggy (he just won’t sit in it lately!) while I looked at pocket details, fabric choices, fit differences between brands and all of the other details that serve as inspiration when I am beginning new designs. I plan to draw up some techical illustrations and start a mood board while Matt and Noah are at their swimming lesson this Sunday. After that, I’ll mull over the construction process in an attempt to create a garment that is a pleasure to sew. This will invariably lead to a number of design changes after which the pattern can be drafted…and onwards the process will go!

These late winter days are an excellent time of year to dig into design work as, although my seed starting station is partially set up, only peppers and celeriac have been sown and the rest must wait until closer to the last frost date. Outdoors the landscape has been covered with frost, snow, or, for the majority of the time, puddles and mud. We have been working at pruning (Matt has taken on the dwarf fruit trees while I’m working on ornamentals and blueberries) but the soil itself is still far too wet to do all that much. This is changing quickly though! This weekend I’m going to do some weeding during nap time as I’ve noticed the weeds have suddenly taken off in the herb bed. That way I’ll be ready to order a big load of mulch to unload over the freshly tidied beds when my parents visit next weekend.

In the meantime though, the evenings are still dark and long so I can work away indoors on pattern development once Noah has been put to bed (ahem…on the nights I have energy to work, that is!).

Another wintery sort of project we have taken on of late is a general shift and tidy of some of our living spaces. We spent two evenings last week as ‘date’ nights. We headed out to our workshop to put on music and tidy and hang tools and create storage systems. After that little bit of effort the workshop is so much more useable! Our house has received the same treatment. We moved all of my sewing equipment and office station to the main floor of our house. Now we have lived here for almost a year (as of this coming March), our daily rythym has taken shape and it has become clear that our lovely second floor studio with windows overlooking the property and a balcony to off one side will just not be used! The nursury is directly across from this room…and I only work when Noah is sleeping! Sewing, typing, and creaking floor boards interfere too much with his sleep.

Thus, the studio will now become our inventory and shipping station. This is just as well because we have another restock of 3000 tissue patterns arriving next week! Matt and his dad are spending the weekend building some sturdy wooden shelving to hold the inventory. Up until this point, our tissue pattern boxes have been piled high in our second floor landing which I would really like to clear up to make into a craft and play room.

My sewing station is now in our sunroom (the very furthest possible point from Noah’s room) and it is a great little corner in which to work. It needs some major work setting it up but it is functional for now and I love that I don’t feel too secluded but it isn’t in anyone’s way (though I have to pack my things up each time I sew so that the power cord and ironing board are not a hazard). I like that Noah can see my work station constantly so he will grow up very aware of what I do for work. Earlier this week we sewed together for the very first time. He plays with my sewing machine knobs quite regularly but, until now, I had never plugged the machine in to show him how it works. He sat in my lap with wide eyes while I sewed him a big pillow for his room. He had a blast stuffing it with me and ran to the sewing machine the next day when I mentioned I had more pillows that I wanted to make.

Outside of studio projects, we have a number of other developments going on this winter on our homestead. Since my Fall post, Matt and my dad have felled, limbed, bucked, and split all of the trees I had intended to hire an arborist to deal with! My dad bought a tractor and has made a new road through one section of the property.

The two of them also re-roofed the chicken coop to combat a frustrating rat problem due to the poor design of the original roof. With the rats long gone, our chickens are happy and have been laying eggs daily all winter long! Our two roosters get along famously and I’ve never once seen them fight. We definitely need at least two more hens though (more likely, three or four!) as Noah eats a lot of eggs and our rooster to hen ratio is still way off.

As winter draws to a close we will be tackling a large rainwater collection and irrigation project. I only had a small veggie garden last year and even then our well was more or less dry mid-summner. I have big garden plans for this summer so a huge rainwater cistern will be essential to irrigate the vegetable bed and orchard. We will be purchasing a 3000 gallon water tank shortly to install by the workshop that we roofed with metal last summer. Once we add gutters to the shop it will collect the rain and a drip system will run from the tank to both garden areas. My past gardens have always suffered mid-summer as I become more and more stingy with water. I hope a timer system and efficient drip tape will lead to happy and healthy plants, all while using the rainwater that is readily available to us throughout a West Coast spring!

To finish up this update with a touch more Thread Theory news: Our next pattern is inching closer and closer to the test sewing stage. Now that the initial sample is sewn, instructions are written and all design details are finalized, it is currently being graded. Next, Matt will format the PDF pattern while I get started on illustrations. I think I will leave the bulk of the illustrations until after I receive the test sewer feedback. We did this for the first time with our Qualicum Bag pattern and it worked very well. Since test sewers only had my written instructions to go by (no images), it really put the clarity of my writing to the test. It was also easier to change construction order and methods as per the tester feedback because I did not have to redo all of the diagrams to reflect the changes.

Anyways, thank you, once again, for the unexpected support and encouragement that you gave me through the survey. You’ve shown me how to embrace this phase of life that I am in and have made it clear that changes of pace and lifestyle should be embraced rather than resisted. I’ll be back with another post when the giveaway winner is announced on February 15th! In the meantime, head here to enter the giveaway, and head here to complete the survey.